With a love of electronics and tinkering passed down from Bill's father

he build his first tattoo machine at age 14 out of wood and a doorbell

buzzer. Working out of a little tattoo shop in his bedroom closet he

started to use plastic and then aluminum for his machines.

Believing that a steel frame would

have a loss in quality because of the magnetic memory (becoming magnetized)

would distort the electromagnetic field and bleed off magnetic energy

generated by the coils.

That is why some machines become

less powerful as they are used, and later on in the day (after sitting)

they become stronger running. The higher quality the iron or steel the

more that they retain a magnetic memory, so time must pass to allow

the frame to de-magnetize.

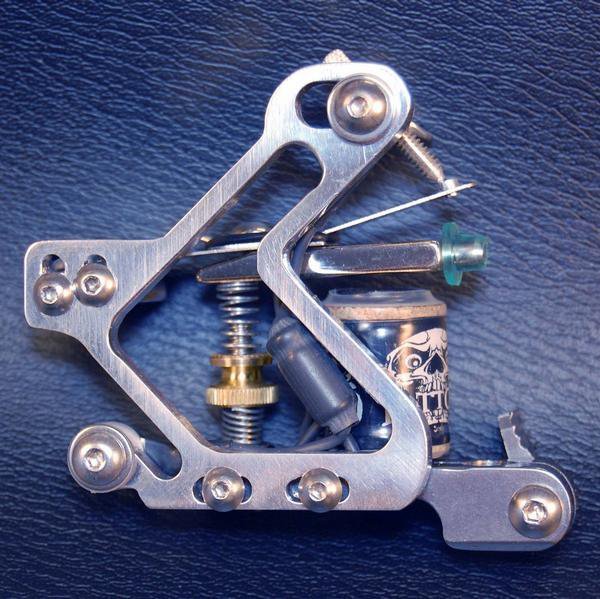

All this led him to never use anything

but aluminum machines to tattoo his whole career.

At one point a member of over 30 Tattoo

clubs and being pen pals with members all over the world enabled Bill

to pick up information that wasn’t readily available.

Exchanging ideas and picking the brains

of every older more experienced tattooist and machine builders he met

like: Paul Rogers, Col Todd, Greg Irons, Bob Shaw, Jack Rudy, Chuck

Eldridge, and Danny Fowler let him to come up with his own concepts

of how machines should be built. Having his own frames cast and later

machined enabled him to keep improving the design.

Finding most coil winders were using

two small of a diameter core. Bill designed thicker 3/8 cores made of

a softer iron. This would give more pull at a lower voltage.

|

Discovering a lighter armature bar made of extra dense, low carbon

alloyed steel would make his single needle machines run faster

with a harmonic motion led him to start drilling them out creating

"Speed Bars"

He also was making square washers for his top springs to avoid

to much stress in one spot causing breakage. Adding O rings on

the springs and on the top of the coils to absorb shock.

|

Very early on Bill found installing a capacitor

in line eliminated the spark at the contact points thus stopping the pits

that formed on them. It took a lot of experimenting to find just the right

size (22mf at 25v). Now that’s a standard on all machines being made these

days.

The drilled out and hand filed aluminum

machines he was building were some of the lightest around. Tattooist from

other states and countries had him build machines for them.

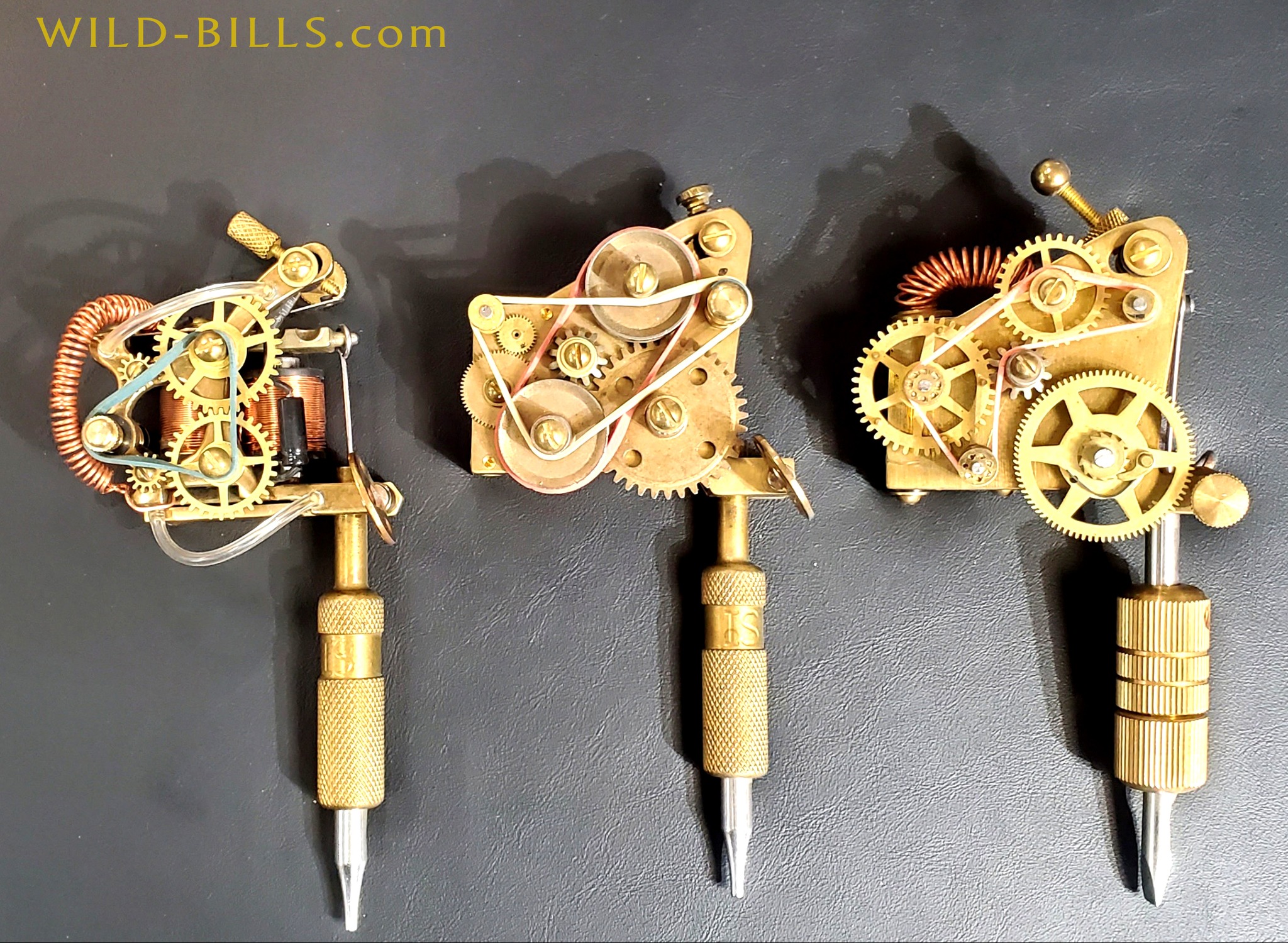

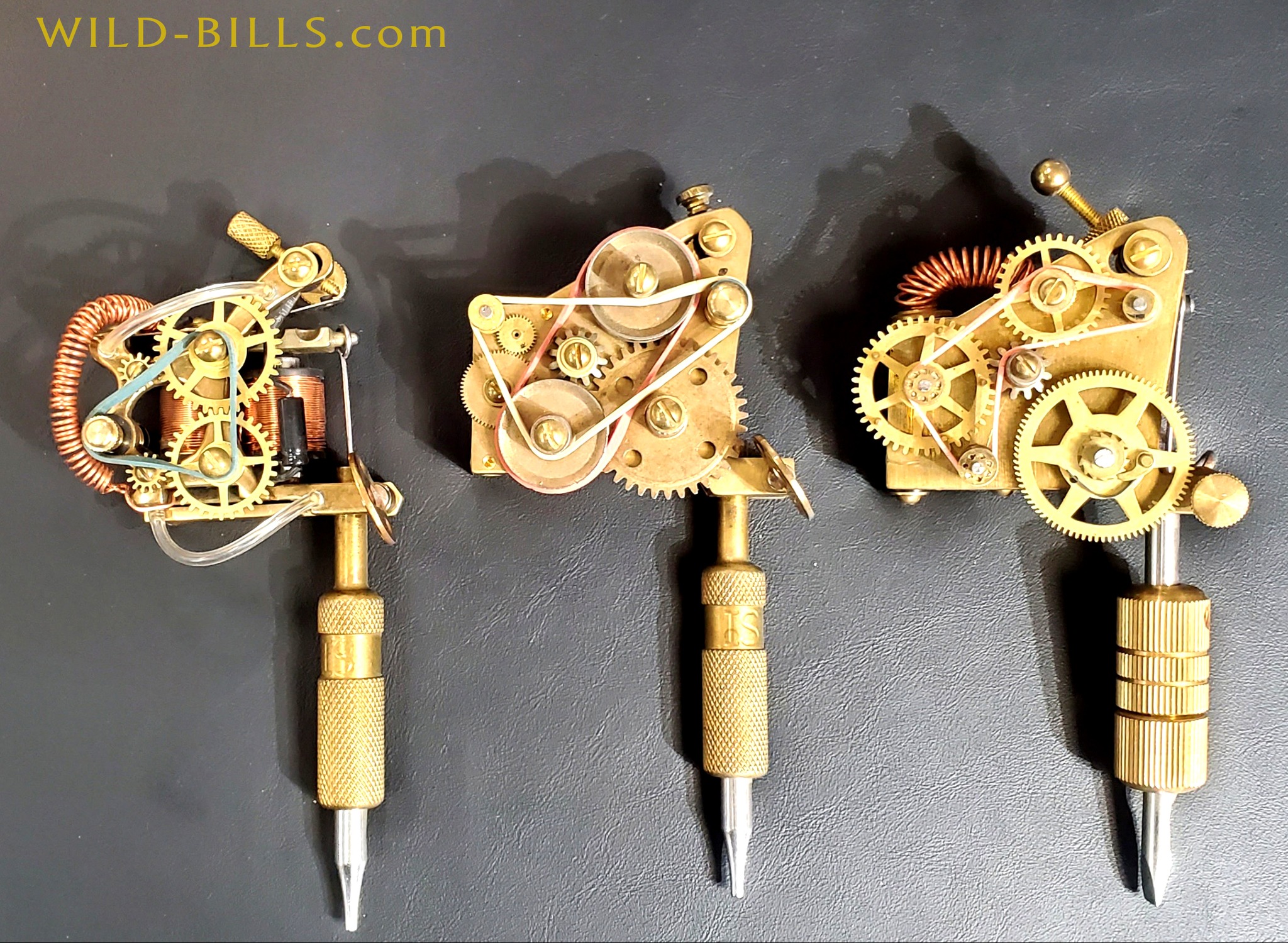

After making a working a solar powered machine (just for fun) he built the

worlds first gasoline powered machine (built out of a model airplane motor).

They can be found at the Tattoo Museum in Fort Bragg CA.

Bill has over 100 machines in his collection.

Mostly aluminum, single coil or custom one of a kind machines.

History of the Tattoo Machine:

Is a very curious device, its origins lie in the first practical use of an electric

motor, a great American inventor and the cooperation of craftsmen from both sides

of the Atlantic.

The Industrial Revolution in both the U.S.A and the U.K. (1750-1915) brought with it an increase in

population and urbanization, as well as new social classes. The manufacturing cities exported their

goods via ships all over the globe and tattooing was a regular pass time amongst the sailors on long

ocean journeys. The working class of the factories, mills and mines were exposed to the tattooing practices

of the sailors and merchant navy in the taverns, markets and gambling houses of the day.

All tattoos were applied by various hand methods inspired by

the native practices of distant lands but, as with most other hand made artisan

practices, tattooing would soon be mechanized. Thomas Alva Edison is often

referred to as the father of the modern electric tattoo machine. It would be

a little more accurate to call him the grandfather of the tattoo machine.

In 1875 there had yet to be a use for this new invention called the electric

motor, capable of transforming electrical current flow into rotary motion. Perhaps

it was the pistons used on the wheels of steam trains that gave Edison the idea

to transfer the circular, rotary action of the electric motor to a linear motion

that could be applied to some purpose. But what could that be? The very first

invention to use an electric motor was known as the Autographic Printing Pen

(Patented in the U.S. Aug.8th 1876). What a very practical idea Mr. Edison.

This device would speed up the printing process by puncturing holes in a stencil,

through which ink could be pressed onto a sheet of paper below.

The machine consisted of a heavy electric motor on the

top of a pen barrel or tube. The needle (there was only one, thick steel needle)

was driven up and down through the barrel, engraving the stencil plate below

with a series of holes following the required design or lettering.

This was an effective use of the electric motor but not

a user friendly one. It was cumbersome and difficult to work with for any

extended period of time. Curiously Edison marketed the device, which sold

well in America, even after he had designed improvements two years earlier

in England (Patented in London Oct. 29th 1875 and in the U.S. Nov.6th 1877)

By using two electromagnetic coils (a tightly wound copper wire around a

soft iron core forming an electro-magnet), springs and contact bars the

machine was lightened considerably.

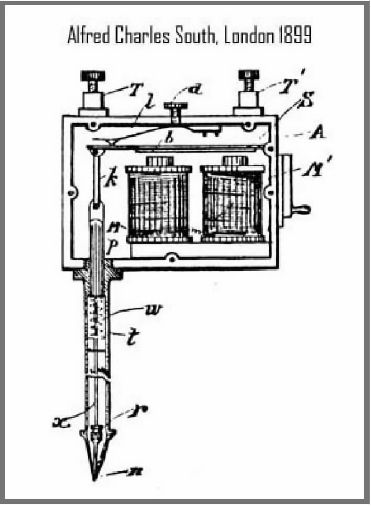

The first American twin coil machine came five years after Alfred South’s British

patent from Charles Wagner of New York (Patented Aug. 23rd 1904,) which had the

coils set side by side; transverse to the frame. The inspiration for this undoubtedly

came from Thomas Edison and his improved engraving instruments as the coil placement

and contact bars are very close in design. The two coils were set side by side

as in a telegraph machine and required a cross shaped armature bar (the reciprocating

metal bar that drives the needles up and down). This was not a simple machine

to manufacture, but sold well to the professional tattooists and amateurs alike.

Charlie Wagner worked closely with Samuel O’Reilly who had previous experience

researching and adapting Edison’s patents.

Each of these early pioneers of tattooing technology saw

the potential to market their devices to the profession and general public

alike. The tattoo kit was born. Machines were sold though magazine ads with

instructions, inks and a book of designs.

Manufactured goods spread around the world and tattoo machines were certainly

bought and sold between the U.S.A. and Briton. The British twin coil machines

made it to the U.S. as well did some of the best tattooists Briton had to offer,

Tom Riley and Sutherland MacDonald, who also patented his own machine (Feb. 12th

1894) which was of a very different design consisting of a cylinder shaped electromagnetic

coil through the center of which the needle bar passed,. While tattooing in America,

Riley had the honorary title of “Professor” bestowed upon him by P.T. Barnum

and was the first tattooist to style himself in this way.

The machines were rudimentary, that is to say, they were designed to work as

manufactured. No room for adjustment, no way to change the function of the machine,

it drove a needle or combination of needles up and down at a set distance. The

frames that held the parts together were purely a practicality.

In modern tattoo machine theory the function of the machine

is determined by the various angles and distances and their relationship to

the elements of the

machine. This is called the “frame geometry”.

It is generally held true that a machine made to line a tattoo is set up differently

from a shading machine. The frame geometry is changed and different effects in

the skin are achieved, depth, power and speed are consequences of this equation

and all parts relate to each other.

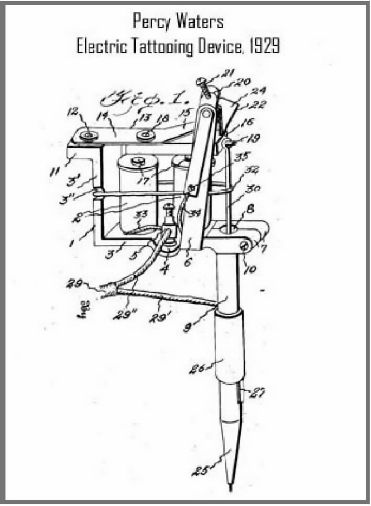

Up until 1929 the design considerations for tattoo machines were primarily weight,

power source, coil size and orientation and fabrication material.

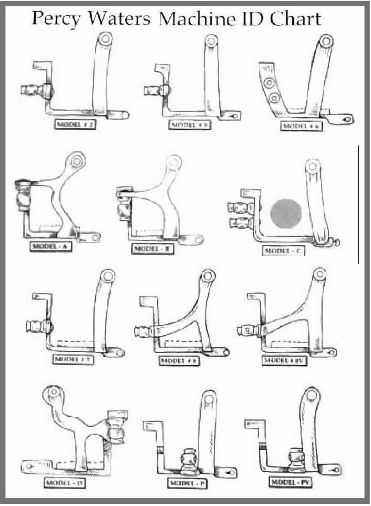

Percy Waters of Detroit, Michigan established probably the largest tattoo supply

company in the world through the 1920s and 1930s. He designed and manufactured

fourteen frame styles and patented what would become the first modern tattoo

machine, in terms of frame geometry, on Aug. 13th 1929.

This tattoo machine design, and the other thirteen, is still in use today. Employing

simple variations such as the angle of the contact screw; this is at the top

of the machine and comes into contact with the springs determining the depth

of the needle stroke, gave rise to a range of machines which can achieve different

results when tattooing.

From Edison’s puncturing machines of 1875, it took almost fifty five years

before someone figured out a tattoo machine could be adjusted and perhaps

one needle

depth was not always what the design needed to be tattooed successfully.

The shape, size and angles associated with the frame of the tattoo machine have

a profound effect on the efficiency and performance of that machine.

Percy Waters set the bar for today’s tattoo machines, the on/off switch that

appeared on his patented machine has disappeared; it was right on top of the

tube grip and could be pushed with the index finger. Early machines were not

designed to be taken apart and cleaned. The tubes or barrels were frequently

welded into place. Tube vices were a later development, and well in use by Percy

Waters time.

It would be fifty years before another tattoo machine patent was granted by the

U.S. Patent Office and in that time tattooing legends took the basic Waters designs

and made them their own. Paul Rogers, Norman “Sailor Jerry” Collins, Milton Zeis,

Owen Jensen and Bill Jones tweaked and tuned and turned them out by the score.

Most of these designs are in production today. All of the originals are solid,

workable instruments and highly collectable.

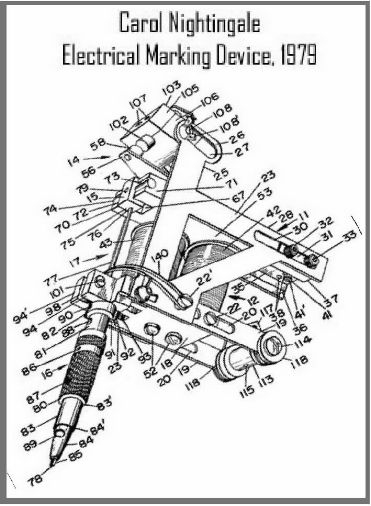

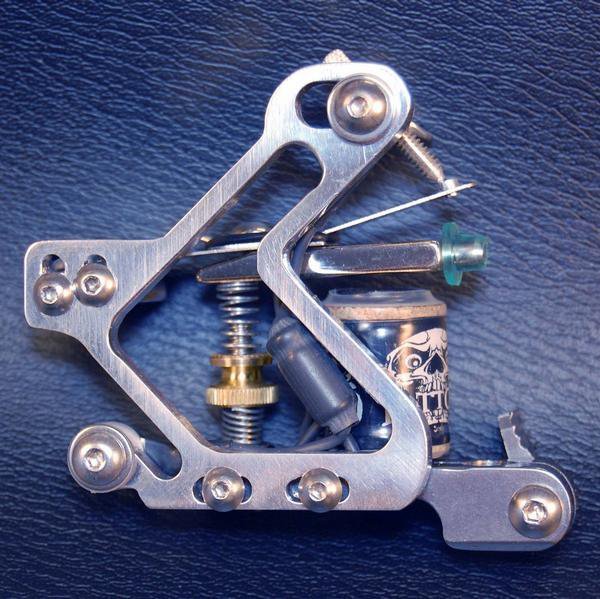

On July 3rd 1979 Carol Nightingale, a Canadian tattooist working in Washington

D.C., patented his “Electrical Marking Device” aka "The Right Hand of America".

When it comes to adjustability, this had it all. Every single component of the

machine was adjustable. By turning a few screws you could slide the coils forward

and backwards as well as the back springs, contact screw housing, armature bar

etc. etc.

It was never a success, there were too many problems with the manufacturing

processes and the machine was just too complicated. But it was inspired work.

Taking the limitations of a set configuration and setting the operator free to

tune the machine any

which way they thought would work. Nightingale sold half a dozen or so.

The materials used to make the frames for tattoo machines have varied greatly over the years. Iron, steel and brass were among

the first used and prevail in modern machines. Bakelite, an early plastic that can be easily machined, has seen its share of

popularity. Wooden frames were predominant as prototypes were developed in the early 1900s. Copper has seen a rise in interest

in recent years even being combined with beryllium, a mildly radioactive metal that stabilizes when alloyed. Some of best modern

machines are made of aluminum. The lighter weight reduces hand fatigue after long hours of tattooing.

The advancement of technology will bring new and exciting developments to the tattoo machine. The recent interest, development

and marketing of a pneumatic tattooing machine has been based on another Tom Edison patent- “The Edison Pneumatic Stencil Pen”

(Jun. 25th 1878) proposed that air pressure, in this case from a compressor, would allow the machine to be lighter and easy to use.

|

|